XPS and EPS comparison

Speaker: Prof. Dr. Thanksgiving Dilmaç

Organizer:

Polystyrene Manufacturers Association

the heat insulation material into small cavities in providing thermal insulation still trapped air (or another gas) d.

By conduction of gas (the vibration of atoms or molecules) heat transfer is very low. However molecules when they find they can move one space, convection (convection) transmit considerable heat. When the gaps in the material grow or become interconnected when the air (or gas), thereby increasing the thermal conductivity of the material. The water content of the material increases the thermal conductivity of the material increases when

STILL AND DRY WEATHER

cheapest, easiest and most environmentally friendly insulation material located. STILL REMAIN FOR AIR AND DRY,

remain within the closed pores are uniformly distributed-the-small

of the water absorption material must be small

Air insulation value gases are smaller

However, they are more expensive, time and place of the material for the air time they increase the thermal conductivity change (aging) and environmental causes of damage are

HEAT INSULATION MATERIALS COMMONLY USED IN BUILDINGS

| Fibrous Materials | FOAM MATERIALS |

|---|---|

| Mineral wool | Polystyrene Foams |

| 1 - Rockwool | Expanded polystyrene foam - EPS |

| 2 - Glass Wool | Extruded polystyrene foam - XPS |

| Wood Wool | polyurethane Foam |

Our country has a high market share of thermal insulation materials Mineral Wool (MW), EPS and xps'

Mineral wool: making glass or stone fibers after dissolving the polymer binder is used to hold and often a combination of these fibers is open-pored insulation material

EPS: Expanded Polystyrene Rigid Foam (EPS-Expanded Polystyrene Rigid Foam), derived from oil and particles şişirl and fusion (bonding) to obtain the product as a foa Tagged, thermoplastic, closed pores, typically white insulation material. Products are also available in today's heat rays reflecting the reduced thermal conductivity of gray

XPS: extruded polystyrene rigid foam (polystyrene rigid foam extruded), derived from petroleum and softened added blowing into the raw material is foamed with gas, thermoplastic, closed pores, color thermal insulation materials

EPS, XPS and BMW some important technical specifications related summary comparison of each product norm EN (European Norm) and other international sources is given on the basis of

THERMAL CONDUCTIVITY

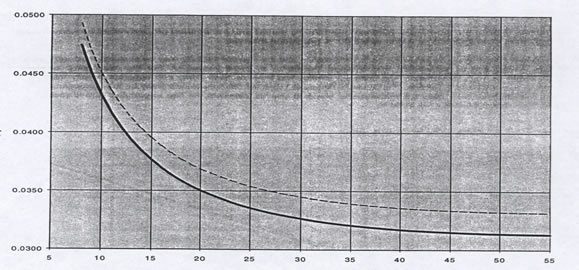

Thermal conductivity depends on the density of the EPS. As density increases, the thermal conductivity decreases. The thermal conductivity of EPS, density of 15-40 kg / m3 in the case of acquisitions value of 0.033 W / mK and 0.040 W / mK between takes values and remain constant throughout the lifetime. Pentane blowing gas used in production. Pentane is displaced air within hours following production.

EPS density variation of the thermal conductivity (EN 13163)

Thermal Conductivity:

XPS blowing in different gases used for the production of gas and air that changes take a long period of time. Therefore, factor determining the XPS thermal conductivity, heat conductivity of the used blowing gas, and while this displacement gas is air. This results from substitution of the gases air, with time, the heat conductivity increases. Aging occurs. XPS different source for the thermal conductivity, due to the blowing gas, 0.028 W / mK and 0.045 W / mK values are given in. Low thermal conductivity gases şişirc that they can damage the ozone and / or for being an important contribution to the global warming, the use of these gases was banned in the European Union. Aging is not observed when using CO2 has a high thermal conductivity.

Mineral wool (glass wool and stone wool) has established the thermal conductivity of 0.040 W / mK range. However, mineral wool are usually lower compressive strength and special handling due to their open pores if they have high water absorption. Structure in the thickness under load of mineral wool becomes wet or if there are no significant decrease is a decrease in thermal resistance that occur during use.

Resistance PRESSURE:

10% compressive stress in the deformation / resistance EN 13162 in the 0.5-500 kPa; 10%

compressive stress in the deformation of the EPS / resistance EN 13163> 30> 500 kPa; XPS

compressive stress at 10% deformation / strength EN 13164> 100-³1000 are given in kPa.

TILT RESISTANCE:

Mineral yünleri’nin eğme dayanımı EN 13162’de 25 - 700 kPa;

EPS’in eğme dayanımı EN 13163’de >50 >750 kPa;

XPS’in eğme dayanımı EN 13164’de 300 - 4000 kPa.

DYNAMIC STIFFNESS:

XPS blowing in different gases used for the production of gas and air that changes take a long period of time. Therefore, factor determining the XPS thermal conductivity, heat conductivity of the used blowing gas, and while this displacement gas is air. This results from substitution of the gases air, with time, the heat conductivity increases. Aging occurs. XPS different source for the thermal conductivity, due to the blowing gas, 0.028 W / mK and 0.045 W / mK values are given in. Low thermal conductivity gases şişirc that they can damage the ozone and / or for being an important contribution to the global warming, the use of these gases was banned in the European Union. Aging is not observed when using CO2 has a high thermal conductivity.

WATER VAPOR diffusion resistance factor (m):

The water vapor resistance eps vary within a wide range depending on the intensity (m = 20 to 100). XPS water vapor resistance, is generally higher (m = 50 to 300). nmineral yünleri water vapor resistance is very low, the air equivalent (m = 1). Water vapor resistance of thermal insulation applications in low external insulation, the insulation should be high from inside the application. Eps vapor resistance can vary in intensity to the desired range, both externally and offers convenient options for thermal insulation applications both from inside. XPS is generally not suitable for high resistance when the external insulation applications; The vapor resistance of mineral wool is often not appropriate to include applications from insulation is very low

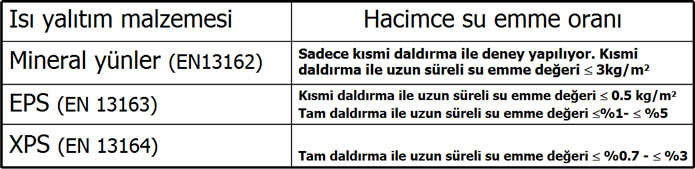

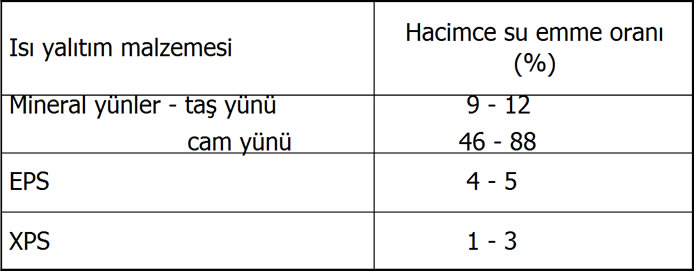

STATE WATER INTAKE:

Mineral Wool, open pores because, if special measures are not taken, the water absorption materials are very high. EPS and XPS closed pores due to water absorption is small.

| Thermal insulation materials | Volume water absorption rate (%) |

|---|---|

| Mineral wool (EN 13162) | Just experiment with partial immersion is done. Long-term water absorption by partial immersion £ 3kg / m2 |

| EPS (EN 13163) < 1 - < 5 | XPS (EN 13164) < 0.7 - < 3 |

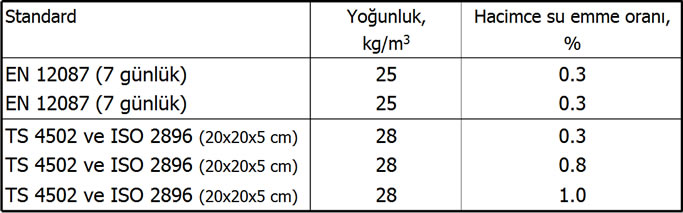

Market random samples taken from the water absorption made according to IS0 4502'y test results

EPS on samples Corlu Trakya University Faculty of Engineering and Technology Nova Chemicals water absorption test results conducted in Europe

FLAMMABILITY STATUS:

Glass and rock mineral wool is the main material of fireproof fibers. However, these fibers are flammable solids polymer binder to hold together and to produce rigid sheet. Reaction to fire the mineral wool, is closely related to the amount of polymer binder.

EPS and XPS building B1 is suitable for use in the flame executive type.

FLUSH WITH ADHERENCE:

Mineral wool of adherence to the traditional cement plaster in EPS and XPS are weak. Cement-based plasters must polymer additives must be used. In adherence with plaster it is good.

AGING

Aging is not seen in the mineral wool and EPS.

XPS thermal conductivity of aging products at inflated HCFCs (thermal conductivity value increases with time) is observed. Those inflated with CO2 aging thermal conductivity of these products can not be seen but is higher than with other HCFC XPS inflated.

Price Level:

Among the most economical material compared to the material EPS.

0.09 Heat conductivity W / mK in order d. Insulation material is higher. Therefore, rather than used alone today, it formed with mineral wool or EPS has been used as the composite member.

AHŞAP YÜNÜ

Geleneksel çimento sıva ile aderansı iyidir.

Isı iletkenlikleri 0.09 W/mK mertebelerindedir. Isı yalıtım malzemesi olarak yüksektir. Bu sebeple, tek başlarına kullanılmaktan ziyade, günümüzde, EPS veya taş yünü ile oluşturulmuş kompozit elemanlar halinde kullanılmaktadır.

Polyurethane foam

Open or closed pores can produce. As they are sold in sheets, it applied as a foam form required on site. adherence with nmetal are high. Adherence to traditional plaster is weak. Combustible materials.

Durability ?

Buy mineral wool, while water absorption values must be specified. Of water-soluble binder, but it is not the fibers of combustible binder, the dimensional stability (especially thickness variations under load) should be remembered that it is important and an open porous material. XPS while blowing gas should be known. Particularly on the thermal conductivity of the blowing gas used in the armor in time and surface (slippery thin layer) it should be remembered that effect. While EPS density and particle shape of cohesion should be examined (the grains together to keep the polygon-honeycomb space should show structures).

The external insulation applications must be noted that in place of the necessary rest time.

Issues to be considered when selecting the insulation material:

Thermal conductivity

Thermal conductivity

Mechanical properties

Mechanical properties

Volume water absorption rate

Volume water absorption rate

Vapor permeability resistance

Vapor permeability resistance

Fayda/Maliyet karşılaştırması

Fayda/Maliyet karşılaştırması

if necessary, sound insulation capability

if necessary, sound insulation capability

Particularly, the coating will be used, it must be known Flammability feature.

Particularly, the coating will be used, it must be known Flammability feature.

INSULATION = better comfort conditions + Clean Air + Energy (Fuel) Foreign exchange gain Saver + Low fuel bill occupants of the improvement in+ the budget and+ the national economy + Development

THERMAL INSULATION, better comfort conditions for the occupants and will mean lower fuel costs across the country with fuel and energy savings as well as clean air, it means foreign exchange earnings and development.

However, the contamination of the environment while generating an insulation material to function perfectly, this scheme does not consume much energy and need to be economical. If, while producing thermal insulation material harm to the ozone layer causing global warming If, on the environment carried out by the thermal insulation material would not be able to talk about this favorable effect

If the insulation material is expensive, the payback period will be longer and the economic contribution of thermal insulation applications that consumers will be reduced.It remains only will provide better comfort conditions back. However, better comfort conditions, that do not harm the ozone layer, which is recycled, environmentally friendly, does not need to consume energy in large quantities during the production and supply you with an inexpensive thermal insulation materials will be an of mind firmer solution.

If the produced thermal insulation materials, thermal insulation applications if the energy savings will be provided with equivalent or greater energy consumption, to mention the energy-saving thermal insulation and will bring the country's development would not be possible.

Source: Polystyrene Manufacturers Association Official Website